Selecting the perfect 3D printer for any businesses can be a challenging task. Here are the top 6 things to consider when choosing the right 3D printer:

3D printing is any of various processes in which material is joined or solidified under computer control to create a three-dimensional object, with material being added together (such as liquid molecules or powder grains being fused together), typically layer by layer.

That means the first thing to consider is which 3D printing technologies suit your application best. For example, is 3D printer being used for production or prototyping purposes? The most common and well known by a number of users is a material extrusion technique called FDM (fused deposition modeling). There are a few other 3D printing technologies to consider, for example, Selective Laser Sintering (SLS), Stereolithography (SLA), Digital Light Processing (DLP), Multi-stream printing, PolyJet and so on. Each 3D printing technology has certain advantages relying upon your application.

The 3D printing material is another important factor to consider when selecting the right 3D printer. Ask, "What materials are best for my particular applications?" Different kinds of 3D printing technologies offer different materials with properties that may suit your application superior to other people. Materials can vary from plastics, metals, and composites.

Will my 3D printer need any unique facility requirements such as extra space requirements, special exhaust system, disposal of any special chemicals, or special post-processing equipment? These necessities can include extra expenses and headaches that probably won't merit your time. Doing a little up-front research will assist you to decide your needs.

What measure parts or normal feature size will you need 3d printed? This can restrain your option relying upon how high of a resolution or how little of a feature size you need to print. Exclusive 3D printers and 3D printing technologies provide an extensive variety of resolutions and tolerances depending at the necessities of your application.

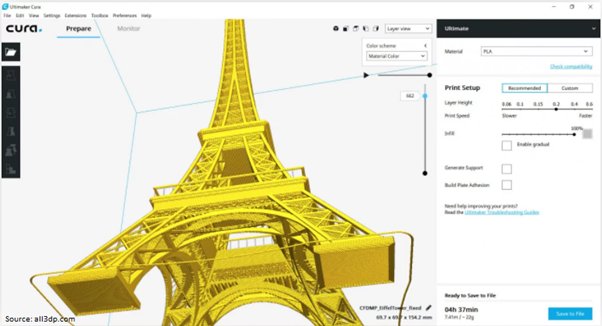

Is the software included with the 3D printer or is it an outsider software? What capabilities are needed to operate and learn the software? Ease of use? These are just some of the questions to ponder when thinking about which 3D printer to buy. Each 3D printing machine and software comes with its own unique learning curve and limitations.

What is your budget? This is the part of your search that you probably have the hardest time answering. It’s hard to think of a particular spending budget of what you are OK with contributing, particular when it’s new technology. Fortunately for you, there are 3D printers for any budget!

Let Engineering Technique know how we can help you as you continued looking for the responses to these inquiries. We have a certified team that has helped organizations of different sizes and diverse industries to find the right 3D printer for their needs.