SOLIDWORKS is the most popular 3D CAD software used widely by manufacturing and engineering companies to take care of the complexities of product development in the dynamic business environment.

SOLIDWORKS boosts strategic alliances, teamwork and unifies systems with integrated solutions for designing of products, its validation, documentation, and thorough product data management.

Across the diverse industries (such as Industrial Equipment, Consumer Goods, Automotive, Manufacturing, Aerospace & Defense, Oil & Gas, Process & Plant, Alternative Energy, Hi-Tech, and Lifesciences) ideal product development programs tend to be in sequential steps. The process starts at designing a perception, followed by creating the structure of the product with all its components and connectors, then moving forward to the testing and optimizing the prospective design for a realistic performance and safety. The final step includes creating and publishing the technological docket inclusive of user manuals, assembly instructions, and manufacturing the product.

With the integrated and concurrent pathway, SOLIDWORKS saves valuable time and money keeping intact the supreme quality and innovative yield. The integrated platform reduces the expensive reworks and helps the users to carry out the product development process steps in a parallel workflow. SOLIDWORKS helps is advantageous in:

• Checking the performance during the designing step thereby eliminating the risk of expensive alternatives.

• Increasing the efficiency in product data management and increasing the accessibility and communicability of design between the stakeholders.

• Creating effective designs without many alterations.

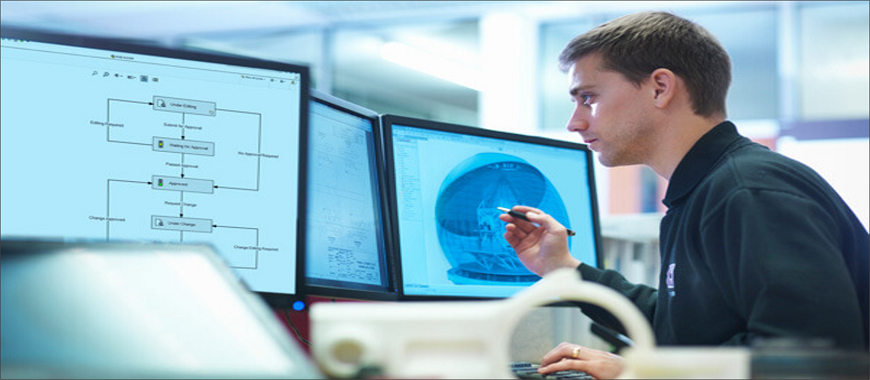

SOLIDWORKS 3D CAD has several tools integrated into the product development platform. The SOLIDWORKS PDM Professional provides a helpful collection of designs that can be used in developing state-of-art designs or creating a dynamic modification of existing designs at a later stage. This tool assists the users to monitor the progress of the product design, take care of the design versions thereby saving valuable time and huge costs. This tool can be effectively used to explore the designs similar to the required ones while using typical components and connectors.

The SOLIDWORKS Simulation proves advantageous in evaluating multiple design alternatives before entering into the manufacturing step.

Read also: Simulation Tools and their Efficiency in Driving Product Design Cycles, Faster

The SOLIDWORKS Visualize tool creates lifelike images for presentations, flyers, brochures, and 3D animations. The tool features automated amendment of changes and displays model variations as and when required. The SOLIDWORKS Inspection scrutinizes the design and makes sure it is ready for manufacturing. Dissemination of the relevant information and data essential for the manufacturing step is governed by SOLIDWORKS MBD. This tool leads the manufacturing process in 3D and therefore, integrates the production process by reducing the course, eliminating the errors, and operates in complete compliance with the industry standards.

The SOLIDWORKS Composer uses the SOLIDWORKS 3D CAD data to design high-resolution 3D images and animations for technical presentations to elucidate the most intricate assembly.

This easy-to-use tool operates directly with the software and benefits users in reducing the time taken for production and cost for technical documentation.

Each of the different tools integrated into the SOLIDWORKS software is easy-to-use and can be implemented faster. The extensible solutions let the users adopt the capabilities needed with maximum flexibility. SOLIDWORKS turns out to be a favorable return on investment by enhancing the competence to launch innovative products in the market at a faster rate and low costs.

Engineering Technique has extensive experience in 3D CAD and its offerings. Having partnered with Dassault Systemes, Engineering Technique has become an authorized reseller of SOLIDWORKS 3D CAD design and modeling software in the Gujarat region of India.

With the integrated capabilities of simulation, motion, routing, and circuit works, SOLIDWORKS 3D CAD becomes a powerful tool for the manufacturing fraternity to accelerate their product development process. Engineering Technique can support you in managing the lifecycle of your product development through the use of SOLIDWORKS 3D CAD.

Read also: Advantages of Designing with SOLIDWORKS 3D CAD Software