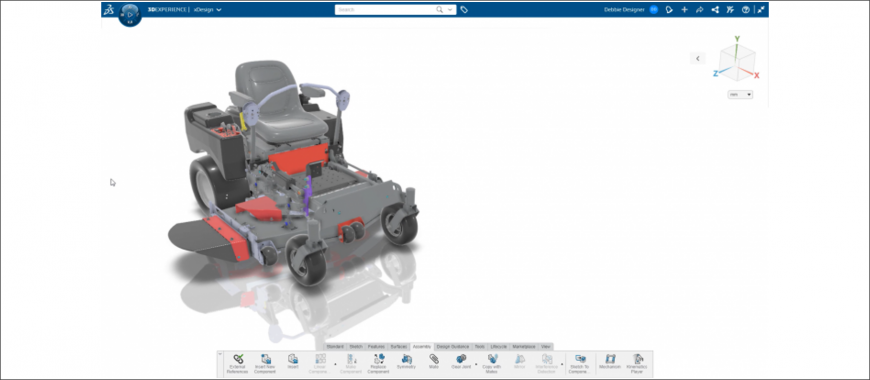

Mechanical design via production is being executed within the cloud: each. single. Day.

But there's a belief available that cloud-based CAD isn’t pretty geared up. The narrative is that perhaps the cloud is suitable for startups and hobbyists however possibly now not properly for production. That can be the case with some cloud offerings, but truth begs to differ in which 3DEXPERIENCE® Works is involved.

Now not simplest are you able to pass from idea to production in a WEB browser, but you can also get entry to your designs 24/7/365 from any tool including a tablet, your home laptop or Chromebook, or a cellphone. That’s a whole new stage of flexibility. Plus, the obstacles to working collectively as a team are nearly removed—regardless of location.

Let’s take a better observe the challenges of building complex elements and assemblies and then consider some of the tools that can permit you to build production-prepared designs in the cloud.

Industrial equipment manufacturers face special design and development demanding situations while constructing conveyor systems, construction devices, industrial robots, and different huge-assembly projects. Electromechanical systems are getting more and more complicated. Assemblies, often massive and multifaceted, can gradual CAD development and growth the chance of troubles with interference and collisions, among other difficulties. And, because engineered-to-order systems are not unusual, each task requires a brand-new design from scratch.

Below are listed some solutions in the 3DEXPERIENCE Works portfolio that assist you to begin dealing with a number of the challenges found in industrial machine design.

The design and engineering solutions on the 3DEXPERIENCE platform offer single modeling surrounding for components and assemblies that can help your consciousness on design and no longer the way you organize your files. Get prepared to say good-bye to the giant (and now and then painful) upfront design making plans about the satisfactory way to shape my assemblies. The single modeling surroundings let you leap in and design proper off the bat because making changes later has very few consequences.

There are not many parts, assemblies, or sub-assemblies in a single modeling environment to worry approximately anymore. The whole thing begins as a “physical product” that may be an element or an assembly. You could create sketches and then turn the ones into 3-D features—or soar directly to 3D with the Parametric Primitives. You may additionally deliver different physical products into the single modeling surroundings and mate them into place, just as you would assume in an assembly environment.

On the pinnacle of that, you may form new sub-assemblies, and if you exchange your mind, you can dissolve them. What approximately the ones capabilities and sketches? Well, they may be decided on and were their physical product. Better still, you could dissolve an element returned into a chain of functions.

As an instance, while growing capabilities, you can decide while it makes feel for all the capabilities to be a part. Then, create any other institution of features, determine while it is a component, and organize the two parts into a subassembly.

And, if you change your thoughts, you can dissolve that sub-assembly and go back to having just the components and upload extra functions if you wish.

Structure systems are a critical part of many design tasks. However, designing structure systems is tough, whether or not you’re designing a fabricated structure with bolted connections, a welded structure, a device frame, fixtures, or something in between.

Generally, to design a structure device, CAD customers first want to sketch a profile and extrude or sweep it to create every member. Next comes trimming all the places wherein the individuals intersect the usage of cut extrude. And ultimately, while the layout is whole, the cut list for manufacturing needs to be manually created.

3D structure creator gives equipment to automate the design of manufacturing-equipped systems. The solution permits you to: create shape individuals based totally on any caricature entities, version edges, or curves; select structure phase profiles from a library of general types and sizes or grow your own; efficaciously perform trim operations at corners and endpoints to create unique (and manufacturable) designs; design with specific structure participants by way of creating custom shape phase profiles based totally on a not unusual profile shape or person-described second cartoon; routinely add plates, gussets, and end caps; add detail to structure designs through including cutouts to structure participants; pace layout to manufacturing with computerized cut lists.

3D motion creator enables you to validate mechanical designs at an early, conceptual stage, stopping ability downstream design or manufacturing issues.

Because 3D motion creator is so smooth to apply, you could hastily compare what-if design eventualities and extensively boom performance in choice-making—across the board—using directly comparing design exchange influences on mechanical system conduct.

3D motion creator affords easy-to-use functionality for kinematic and dynamic analysis of any mechanism in browser-primarily based surroundings. At once prepare a movement simulation for kinematic evaluation primarily based on existing 3D designs with the aid of deciding on products, parts, or engineering connections (friends).

Working with a kinematics participant, you can fast analyze the kinematic system behavior. After running an analysis, you can review results with animation or second plots. Improve the simulation with drivers, forces, torques, and 3D contacts or upload dynamic modeling elements, which include a helical spring, to create a dynamic motion simulation.

Conclusion

Lots of the DNA that tens of millions of customers worldwide know and love from SOLIDWORKS® desktop is built into 3DEXPERIENCE Works solutions. The action bar is similar to the Command manager in SOLIDWORKS. All of your contextual menus are there—once more, just like SOLIDWORKS—due to the fact 3DEXPERIENCE Works design and engineering solutions realize what menus which you need to look at subsequent to keep your design primarily based on what you pick.

When connected and dealing with design data on the 3DEXPERIENCE platform, everybody for your group works from a single model of the product within the same surroundings. Collaboration is rapid and the design data is robotically managed at the platform, so each human beings and data stay in sync.

To examine more approximately 3DEXPERIENCE Works design and engineering solutions and the way you can construct production-prepared components and assemblies, contact us.