Fused Deposition Modeling (FDM) is a useful additive manufacturing process that helps extrude materials in diverse forms and shapes. With FDM, engineers can build objects by selectively depositing melted components (thermoplastic polymers) in a determined path with consistent layers.

Since FDM is a popular 3D Printing technology, most 3D printing machines follow the trend globally and is quite convenient for making varied engineering products seamlessly.

Every top 3D printing company relies on its best budget 3D printer to explore the capabilities and limitations of this approach, focus on getting the best results. The 3D printer cost differs from one to another based on its capabilities, accuracy, and intensity.

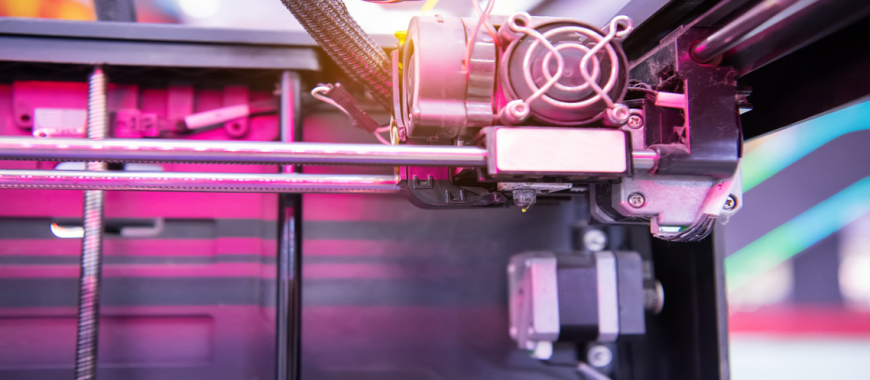

Pioneered by Stratasys in 1990, Fused Deposition Modeling (FDM) 3D printers are now extremely popular for leveraging the technology called Fused Filament Fabrication (FFF). The process is also touted as Plastic Jet Printing (PJP). The tools include the printer, nozzles, and raw materials (thermoplastic filaments).

The FDM 3D printer relies on its platform that is usually made of metal, ceramic, or hard plastic.

FDM 3D printers use a belt and/ or lead screw systems for the entire extrusion assembly powered by a motorized system. The stepper motor advances the thermoplastic material right into the printer head. All movements are controlled by a computer.

The raw material includes production-grade thermoplastics, while metal is preferred as well for industrial 3D printers. The raw material needs to be constantly melted down with heat exposure and re-solidified with heat withdrawal. The thermoplastic filament is coiled on a mounted spool and ushered in through the printer nozzle. FDM 3D printers at their best allow nozzle temperature to match the glass transition temperature for extruded material. Hence, the extrusion happens in a semi-liquid state that transforms into a solid-state almost immediately. Engineers can thus, ensure impeccable dimensional accuracy with FDM 3D printing.

Other than thermoplastics, nylon, Acrylonitrile Butadiene Styrene (ABS), polycarbonates, and polystyrene are popular raw materials, used extensively for the 3D printing process.

The FDM 3D Printing Process

FDM 3D printer in India deposits raw material on every layer, and the next along the axis, ensuring outstanding accuracy of the output. The accuracy depends on the minimum distance travelled by the nozzle vertically and minimally. The minimal movement ensures that the nozzle captures the design through the sinusoid to perfection. For some 3D printers in India, the best dimensional accuracy recorded till now is nearly 0.127 mm. The choice of raw material is crucial in ensuring the stability of the structure and the cost of printing time increases with the accuracy of the model.

Some advantages of FDM 3D printers include:

These FDM 3D Printers are handy in the automotive and real estate sector while playing an important role in aerospace, education, manufacturing, medical, architectural, and industrial applications. FDM 3D printers in India are valued for money and continue to make an impression in various engineering spheres.

Engineering Technique is a top 3D printing company offering DAMboy - one of the most affordable FDM 3D printers offering impeccable accuracy and precision in its outputs.

The DAMboy FDM 3D printer, targeted towards engineering students helps them explore the technology and realize useful concepts with the 3-dimensional models in a jiffy. DAMboy also addresses pre-determined and accurate prototyping needs for varied industries. Contact us here to know more.