Inspiration regularly fuels innovation. You must be wondering about which innovation I am talking? Well, this innovation is concerning the virtual simulation that almost all of the manufacturing companies across all the industries are using. 3D virtual simulation is being used as an engineering tool to synthesize and define products.

Simulation technology helps the design engineers to make better design decisions by providing the proper tools, right hardware at the proper time which are crucial factors for any design process. Simulation is acting as a design driver for both product and process. This results in better products at a faster rate and lower cost rates.

Have you ever come across such questions as- whether the moving parts will clash with each other, the weight a product can carry, deformation during stresses, proper circulation of heat and air through the design?

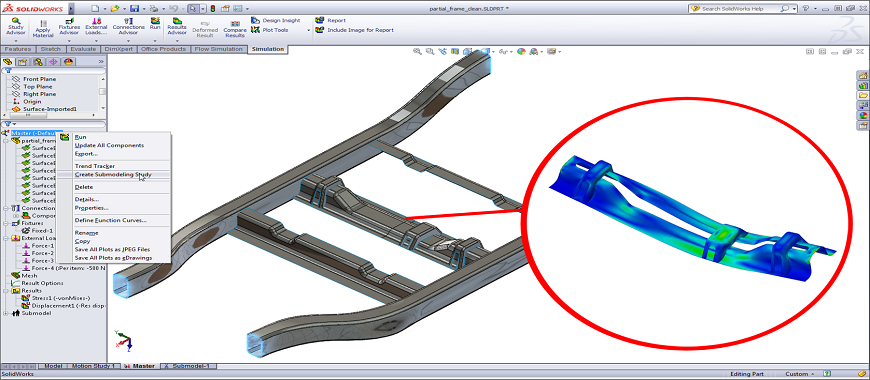

If all these questions worry you then SOLIDWORKS Simulation is the right answer for you because SOLIDWORKS Simulation enables you to subject your designs under real-time conditions like stresses, impact, heat, airflow, etc. It also helps in optimizing the design for maximum performance by helping prevent errors during the early stages of the design process. If the errors are discovered late in the design process, then it becomes difficult to rectify the errors. This helps in making the product development process linear and more efficient.

The various SOLIDWORKS Simulation tools or solutions available in the market are:

• SOLIDWORKS Motion Simulation: SOLIDWORKS Motion helps in ensuring the performance of the product by performing structural analysis. Simulation helps in assembly motion analysis. It not only determines the physical movements of the assembly under load, as well as time-based motion and event-based motion.

• SOLIDWORKS Flow Simulation: SOLIDWORKS Flow Simulation intuitive Computational Fluid Dynamics (CFD) enables the designer to simulate fluid flow, heat transfer, and fluid forces. It also analyses the effects of fluid flow, heat transfer on surrounding components.

• SOLIDWORKS Plastic: SOLIDWORKS Plastics injection molding simulation helps to determine the melted plastic flows during the injection molding process. SOLIDWORKS Plastics helps the user to minimize the defects by enabling them to change part or mold geometry, processing conditions, or the plastic material. This ultimately saves time and money.

• SOLIDWORKS Sustainability: SOLIDWORKS Sustainability performs real-time environmental assessments and provides instant feedback which helps you to make changes in your design very quickly.

• Reduces Product Development Cost: Reduces the need for prototyping and also lessens outsourcing costs as performance and functionality testing is possible internally.

• Enhances product efficiency: Improves the performance of the product like increased horsepower and lower pressure drop.

• Shorten time-to-market: Optimizes the assembly performance by parts verification, reduces the need for physical prototyping, and optimizes product development.

Simulation technology is the best solution for all companies as it helps the designer to identify the defects at the earlier stage of the design process, helps the designer from making any big mistake and thus it saves cost to the company.

Thanks for reading this blog post. Engineering Technique offers SOLIDWORKS Simulation software solutions and services at affordable prices. If you need help with your simulation projects let us know and we will be glad to help.